Two Stage Air Compressor

₹145,000.00

Model Name- SAC-30/50/75/100/150

A two-stage reciprocating air compressor in GA is ideal for most demanding industrial applications. They are much stronger than single-stage compressors and can handle more pressure and more capacity. Today we’re discussing how these compressors work.

Duty cycle: The duty cycle of almost all two-stage air compressors is 100%, which is one of the reasons they are viewed as being more powerful and durable. This duty cycle indicates that the compressor can run nonstop, without needing time to cool down. In contrast, most single-stage air compressors have a duty cycle of 50% or 75%.

Two stage air compressors: With two-stage air compressors, the air is compressed in two stages; in between the stages, the air is cooled.

Stage 1: Air is compressed to medium level, which is the big cylinder/piston. It moves a high volume of air, but at a low pressure.

Cooler: Air is cooled back to a much lower level, making the compressor more efficient and reducing stress.

Stage 2: The air is compressed further to the end pressure, which is the small cylinder/piston. It moves a lower volume of air, but at a higher pressure.

On some models, you can clearly see the two stages, while on others, the low pressure and the high-pressure cylinders are cast in one block, making it look like a single-stage compressor.

Pressure: You need to figure out how much pressure you need. two-stage reciprocating compressors in GA can get up to 175 psi. If you only need 125 psi, it’s better to choose a compressor with a lower maximum pressure, but at a higher capacity.

Capacity: Like with any type of compressor, you need to know (approximately) the amount of air that you will be using before making your decision. If you are unsure about what capacity you need, be sure to review the air compressor buying guide. two-stage reciprocating compressors go up to about 50 CFM (cubic feet per minute); if you need more, a rotary screw compressor might be a better option.

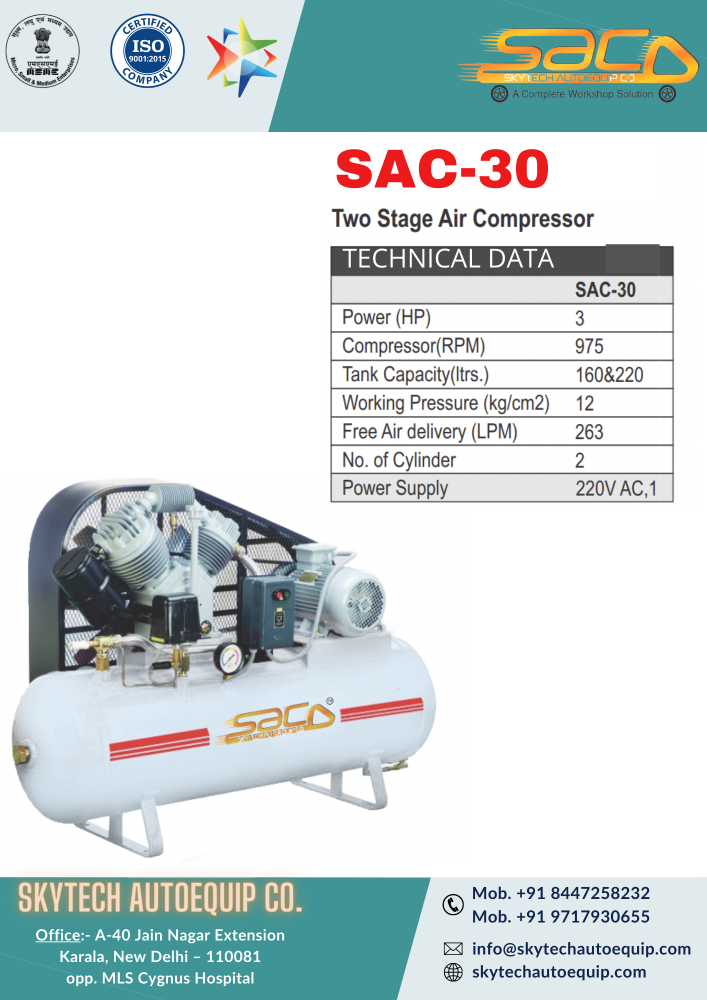

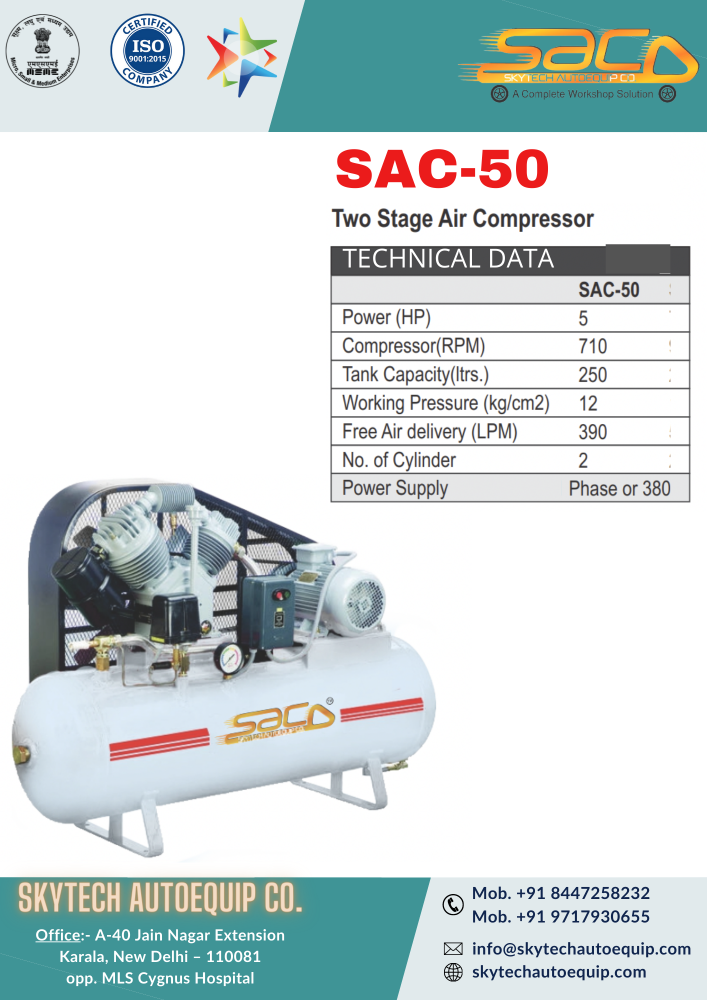

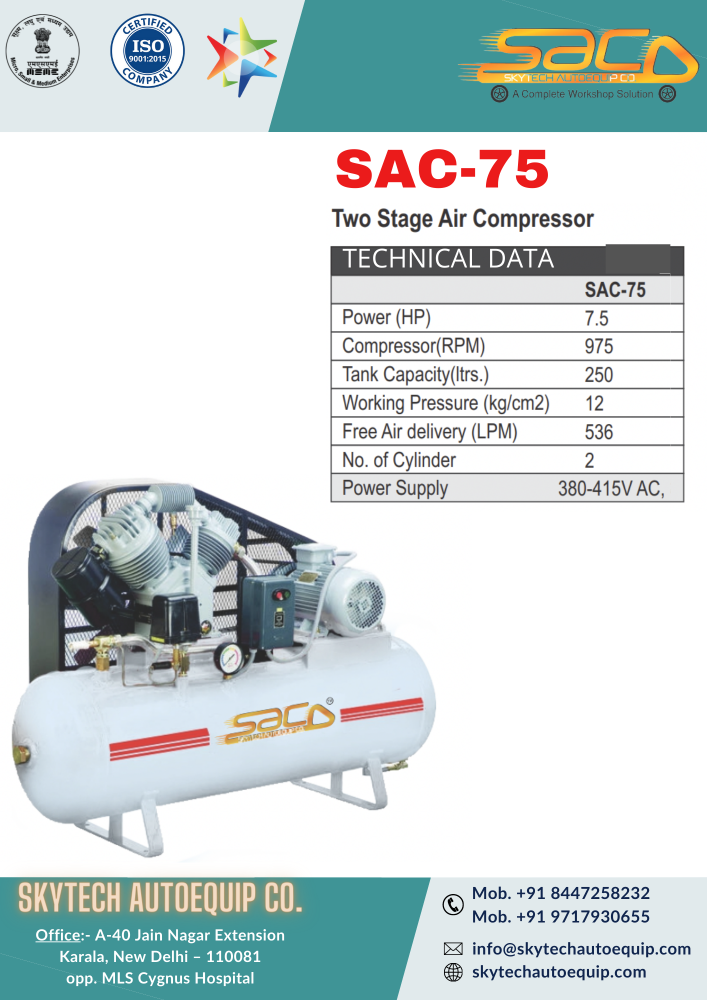

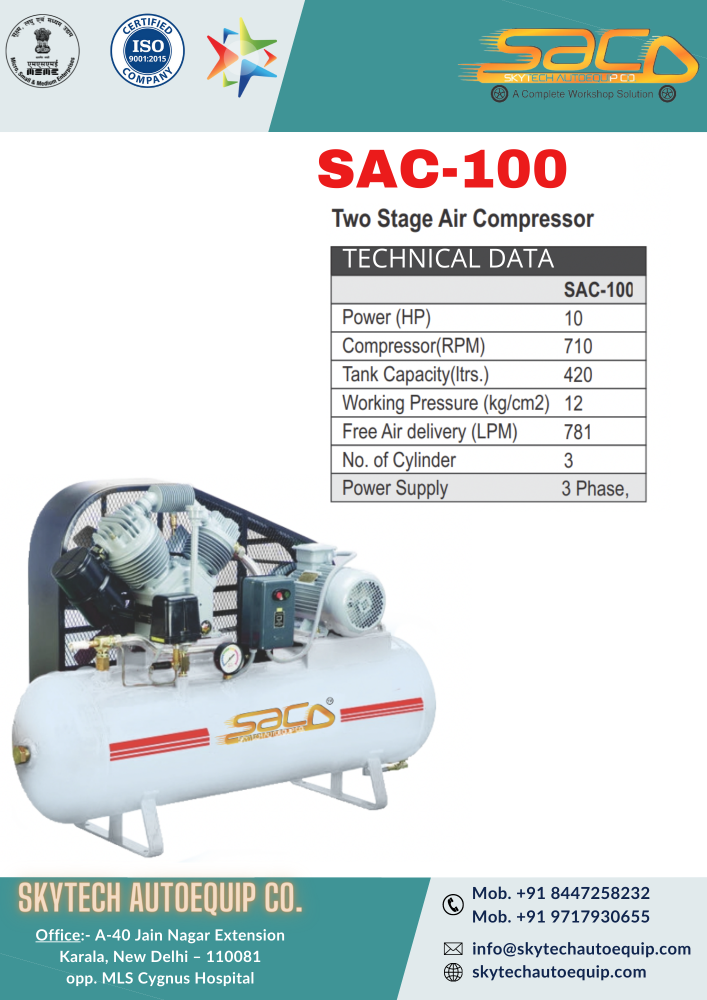

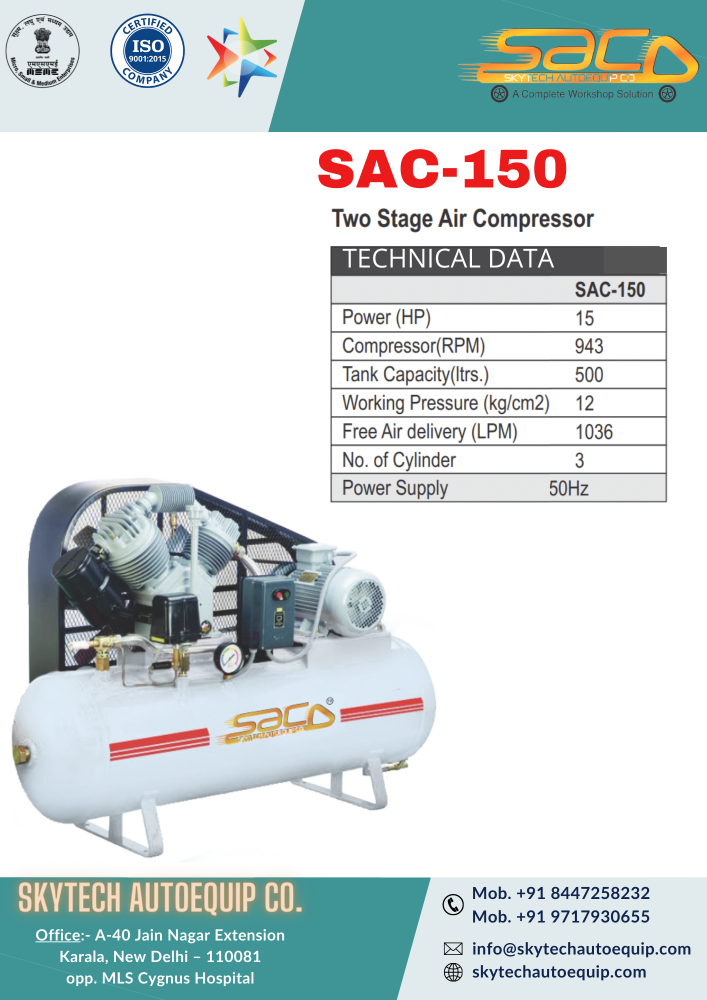

| TECHNICAL DATA | |||||

| SAC-30 | SAC-50 | SAC-75 | SAC-100 | SAC-150 | |

| Power (HP) | 3 | 5 | 7.5 | 10 | 15 |

| Compressor(RPM) | 975 | 710 | 975 | 710 | 943 |

| Tank Capacity(ltrs.) | 160&220 | 250 | 250 | 420 | 500 |

| Working Pressure (kg/cm2) | 12 | 12 | 12 | 12 | 12 |

| Free Air delivery (LPM) | 263 | 390 | 536 | 781 | 1036 |

| No. of Cylinder | 2 | 2 | 2 | 3 | 3 |

| Power Supply | 220V AC,1 Phase or 380-415V AC, 3 Phase, 50Hz | 380-415V AC, 3 Phase, 50Hz | 380-415V AC, 3 Phase, 50Hz | 380-415V AC, 3 Phase, 50Hz | 380-415V AC, 3 Phase, 50Hz |